Aims Our aim is to help reduce your costs and accelerate your productivity by simplifying your quality control systems. We do this using LabVIEW.

Why Test? Testing takes time and costs money. Often it requries skilled staff to get it right.

If you get it wrong then your product can fail in the field, leading to increased return costs and loss of brand reputation. Testing in-house is by far the most effective way of catching production errors.

LabVIEW

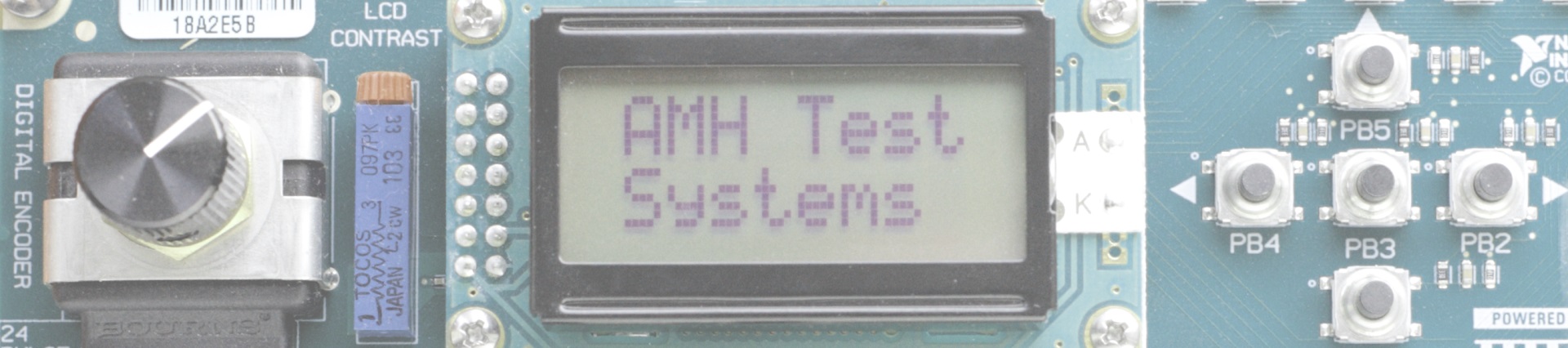

LabVIEW allows simple yet powerful test systems to be made around a simple PC. It allows for rapid, repeatable testing of pretty much any electro-mechanical device. If there is a sensor for it, LabVIEW can measure it and control it. Automatically.

Industries

AMH Test Systems has experience working across a range of industries: garden tools, medical research, engine testing, batteries and electical vehicles and materials research. Most work is carried out under a Non-Discolsure Agreement.

|